As with many devices, today’s shotgun microphone wasn’t a single invention, but was rather the cumulative result of several innovations over time. Four of these innovations stand out in the history of the shotgun microphone: Mason’s and Marshall’s Tubular Directional Microphone, Olson’s electroacoustical apparatus, Sennheiser’s MD 82, and Beaverson’s and Ramsey’s unidirectional microphone. If you’re a microphone geek like me, it’s interesting to trace the development of the modern shotgun microphone through these three seminal inventions.

- What exactly is a shotgun microphone?

- Mason's and Marshall's Tubular Directional Microphone

- H.F. Olson's U.S. patent 2,228,286 for "electroacoustical apparatus"

- Sennheiser's MD 82

- Beaverson's and Ramsey's unidirectional microphone, aka the Electro-Voice Cardiline

- What's happened in the sixty years since the Cardiline?

- References

What exactly is a shotgun microphone?

Before you can trace something’s history, you have to first define exactly what that something is.

A shotgun microphone is a form of line microphone. A line microphone provides a highly directional polar response by exploiting destructive interference between sounds received on multiple ports arranged along a line. So, if you really want to understand the history of shotgun microphones, you need to understand the history of line microphones in general.

By the way, if you want to know more about how line microphones work, check out my detailed post on how shotgun microphones work. But read on if you’re interested in line microphone history.

Mason’s and Marshall’s Tubular Directional Microphone

The first line microphone wasn’t the shotgun microphone; it was the clustered-tube “machine-gun” microphone.

The machine-gun microphone started out as a device called the “Acoustic Impedance Element”, which was invented by W. P. Mason of Bell Telephone Laboratories (U.S. patent 1,795,874, filed September 22, 1927 and issued March 10, 1931). Bell Telephone Laboratories (which was spun-off from Western Electric Corporation in 1925) was responsible for much of the world’s research in communications technology in early part of the twentieth century, and Warren Mason was one of the most prolific researchers at Bell Labs.

The purpose of Mason’s Acoustic Impedance Element was to provide a constant acoustic resistance over a wide frequency range. He achieved this using a cluster of tubes of varying length. There are many possible applications for such a device, but Mason’s 1,795,874 patent didn’t mention directional microphones as one of them.

However, despite the fact that his 1,795,874 patent didn’t mention it, Mason either already knew or quickly figured out that it could enable a new type of highly directional microphone.

And so, in 1937, Western Electric Corporation (which had first rights to Bell Labs’ inventions) introduced the E99098. The E99098 was essentially Mason’s clustered-tube Acoustic Impedance Element in the form of an attachment for the existing Western Electric 618A omnidirectional microphone. The 618A/E99098 was marketed as long-range directional microphone for the film industry. For obvious reasons, this microphone was soon nicknamed the “machine-gun microphone”:

(Photo citation: Western Electric Company, “Western Electric 618A/E99098,” UGA Special Collections Library Online Exhibitions, accessed December 20, 2021, https://digilab.libs.uga.edu/scl/items/show/841)

As far as I can determine, the Western Electric 618A/E99098 was the first commercial line microphone.

Then, in 1939, Mason and R. N. Marshall authored a very interesting paper [1] referencing the Western Electric 618A/E99098, and discussing the theory and actual performance of this new type of directional microphone. Among other things, this paper provides formulas for calculating the directivity of such microphones, compares their performance to parabolic dishes, and discusses some real-world applications.

On December 17, 1940, Mason’s U.S. patent 2,225,312 issued. This patent (which was filed about the same time Mason’s and Marshall’s paper was published) disclosed an advanced form of machine-gun microphone in which the cross-sectional areas (in addition to the lengths) of the tubes were varied to further increase directivity. But as far as I know, such a microphone was never produced.

H.F. Olson’s U.S. patent 2,228,286 for “electroacoustical apparatus”

The next steps in the development of the line microphone were made by H. F. Olson, another amazingly prolific engineer/inventor—but at the RCA Victor Corporation, rather than at Bell Labs. These innovations were disclosed in Olson’s U.S. patent 2,228,886, which was filed on October 31, 1938 and issued on January 14, 1941.

Olson’s improvements to the machine-gun microphone

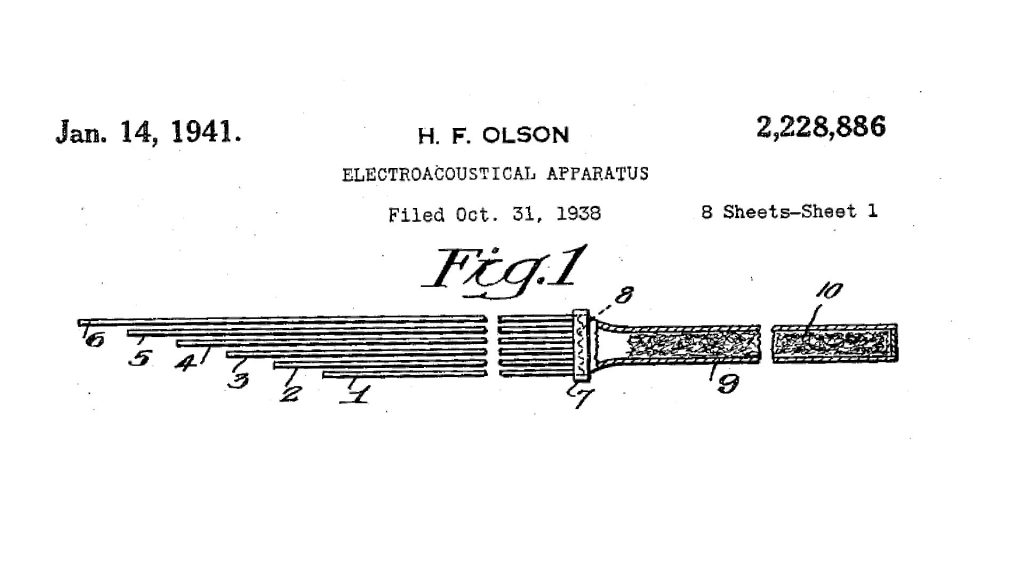

The embodiments shown in the first fourteen figures of Olson’s 2,228,886 patent were improvements to the machine-gun microphone.

Many of these improvements were aimed at enabling the use of a pressure-gradient microphone element (instead of the pressure element used in Mason’s microphone). For good frequency response, both sides of a pressure-gradient microphone should see the same constant acoustic resistance over over the microphone’s operating bandwidth, and Olson showed several ways of accomplishing this.

His simplest solution was to back-load the microphone with a tube filled with damping material so that it would present the same acoustic impedance to the microphone as the machine-gun tube cluster:

Olson also described how a machine-gun microphone’s low-frequency response could be intentionally restricted by making the rear damping tube one-quarter wavelength long at the desired cut-off frequency. He would later build on this idea in perhaps his most significant line-microphone patent, but we’ll get to that later.

Another series of improvements to the machine-gun microphone disclosed in the 2,228,886 patent were aimed at providing constant directivity. Like any directional acoustic device, a machine-gun microphone’s directivity is frequency-dependent: its polar pattern becomes narrower with increasing frequency. As a result, it can conceivably be too directional at high frequencies (so that even a small error in aiming the microphone at the source can kill the high-frequency response). Olson showed several ways to make a machine-gun microphone “act shorter” with increasing frequency, thereby flattening the directivity-versus-frequency characteristic. However, it’s not clear if such constant-directivity machine-gun microphones were ever produced.

RCA did produce at least one version of Olson’s basic machine-gun microphone, the RCA High Sensitivity Varidirectional Microphone MI-10006-A, around 1960. A photo of, and specifications for, this mic can be found on page 18 of the fifth edition of the RCA Broadcast Equipment Catalog (1962), accessible at http://thehistoryofrecording.com/Literature/RCA/RCA-Broadcast-Equipment-Catalog-1962-5th-Edition.pdf.

It’s clear that the 10006-A used Olson’s tube cluster, but the type of microphone element isn’t obvious. But here are a few interesting specs from the above reference:

- The tube cluster (which was called the “MI-10008 Unidirectional Attachment”) could be removed to convert the 10006-A to a standard cardioid pattern (hence the name “Varidirectional”).

- Overall length was 22 inches with the Unidirectional attachment.

- Weight was 1 pound, 12 ounces without the Unidirectional attachment, but I couldn’t find the weight with the attachment.

- RCA quoted a useful range with the unidirectional attachment of four times that of a conventional microphone.

As far as I know, aside from the MI-100006-A and the previously-discussed Western Electric 618A/E99098, no other machine-gun type microphones were ever produced commercially in large numbers. However, the machine-gun mic has one potential performance benefit over the modern interference-tube microphone: in an interference tube, sound pressure admitted by one slot can escape from another slot before it reaches the microphone, but that isn’t an issue with the machine-gun mic.

On the other hand, a machine-gun mic is heavier, and more expensive to manufacture, than an interference-tube mic. And that’s probably why they’re considered obsolete.

Olson’s interference tube microphone

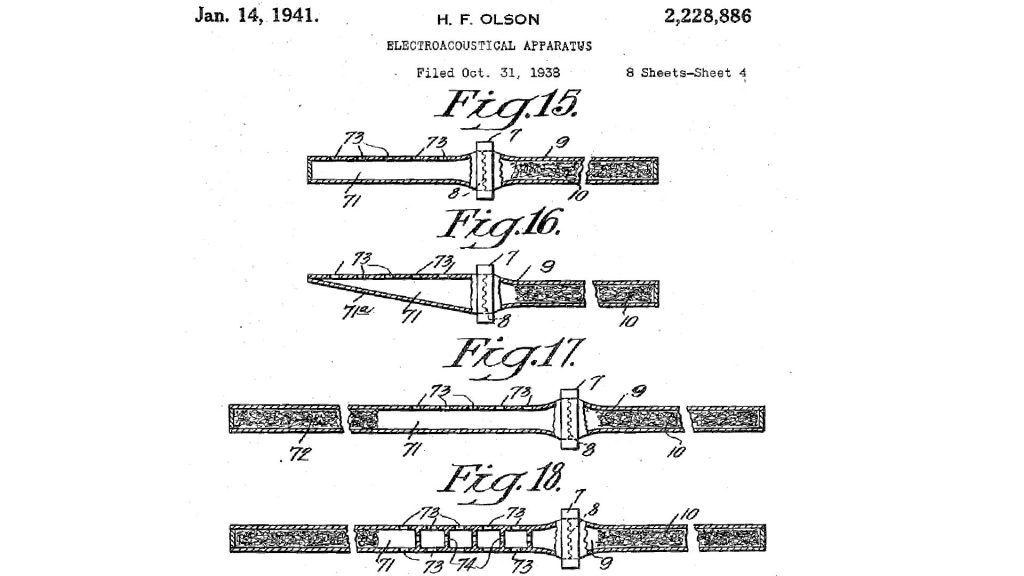

If you don’t study Olson’s 2,228,886 patent carefully, you might miss the fact that he also invented the interference tube microphone. His Figs. 15 – 18 showed four versions of this:

Olson’s interference-tube microphones look a little different from modern versions:

- Instead of the slots in the interference tubes of modern shotgun microphones, Olson’s tubes (71) are perforated with holes (73).

- Like his machine-gun microphones, Olson’s interference-tube microphones use a pressure-gradient microphone element that’s back-loaded with a damping tube (9).

- The front end of the interference (71) tube is closed, rather than open. This might seem surprising at first, but on-axis sound still reaches the microphone via the holes (73). And if the front of the tube were open, off-axis sound admitted from the front could have a different amplitude than the components admitted by the holes, potentially reducing the attenuation due to destructive interference.

- However, Olson recognized that internal reflections from the closed end of the tube could cause standing waves, so he disclosed versions using a tapered interference tube (Fig. 16), and a damped interference tube (Fig. 17).

- Olson also recognized that there could be coupling between the holes (73), which could spoil the off-axis rejection. So he showed a version (Fig. 18) that used internal baffles and orifices (74) to isolate the holes (73).

As far as I know, these microphones were never commercially produced, but the acoustic principles that motivated Olson’s innovations have had a powerful influence on modern shotgun microphone design.

Sennheiser’s MD 82

I can’t find a patent that covers it, but the Sennheiser MD 82, introduced in 1956, appears to be the first practical shotgun mic that doesn’t use a tube cluster. In fact, the history page at the website of Sennheiser Ltd. takes credit for MD 82 as the first shotgun microphone in commercial production.

I can’t find any details about the operation of the MD 82. However, instead of the slots in a modern interference tube, the MD 82 appears to have used an array of fins to admit off-axis sound. In effect, the space between each pair of fins functioned as a deep slot, and the slot depth was apparently chosen to resonate at a frequency which would improve the MD 82’s high-frequency response.

I also can’t find any confirmation of the type of microphone element used in the MD 82, but from photos on eBay it appears to be a pressure-type element which has an isotropic response. Therefore, like Olson’s version, the MD 82 provided minimal rejection of low-frequency sounds arriving from 180 degrees off-axis.

The BBC published a report [2] documenting their testing of the MD 82, and I discuss some of the test results on my detailed post on how shotgun microphones work.

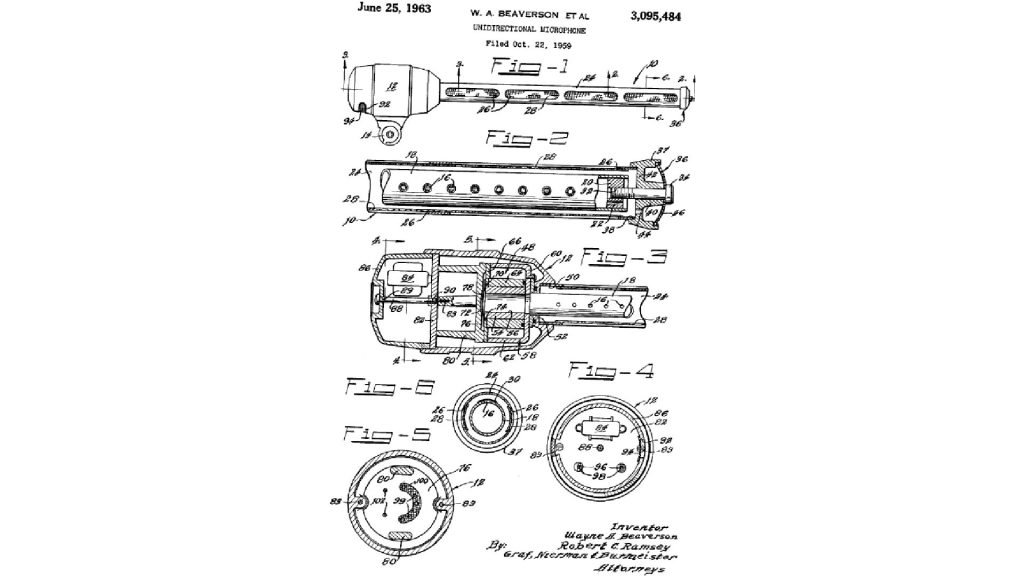

Beaverson’s and Ramsey’s unidirectional microphone, aka the Electro-Voice Cardiline

The final major development leading up to the modern shotgun microphone seems to be the “Unidirectional Microphone” disclosed by Wayne A. Beaverson and Robert C. Ramsey in U.S. patent 3,095,484, filed on October 22, 1959 and issued on June 25, 1963. One of their key innovations was the use of a special cardioid microphone element to improve the low-frequency directivity. Thus, this device could be considered the direct ancestor of today’s shotgun mics, all of which combine an interference tube with some type of cardioid element.

The cardioid element disclosed by Beaverson and Ramsey was innovative in the sense that the acoustic path to the rear of the diaphragm functioned as a low-pass filter, with the cutoff frequency approximately equal to the critical frequency of the interference tube. Thus, the microphone element functioned as a cardioid microphone at low frequencies, but as an omnidirectional element at higher frequencies at which the interference tube became effective.

The patent was assigned to Electro-Voice, which produced a series of “Cardiline” shotgun microphones (the Electro-Voice EV642, 643, & 644) that were remarkably similar to the device shown in the patent drawings. Mitchell’s Microphones [3] discusses these microphones and provides some pics.

What’s happened in the sixty years since the Cardiline?

Of course, shotgun microphone design has advanced significantly since the introduction of the Cardiline in the early 1960’s, but not as quickly as in the preceding forty years.

During those early years, giants like Mason and Olson were making fundamental advances in acoustics, and the Beaverson and Ramsey hybrid cardioid/interference tube microphone was truly ingenious. Those were revolutionary developments.

Progress since then has been mostly evolutionary. Today’s shotgun microphones certainly work better than the line microphones of the 1960’s, but the difference isn’t as great as you might expect. For example, see my comparison of modern and classic shotgun microphones in my detailed post on how shotgun microphones work.

However, I think we’re on the verge of another wave of major advances, thanks to Digital Signal Processing (DSP). There have already been two attempts to exploit DSP to improve shotgun microphone performance: the Audio-Technica AT895 (circa 2004, now discontinued) and the Schoeps SuperCMIT 2U (circa 2010, still in production). Both used/use DSP, along with additional microphone element(s), to provide significantly greater suppression of off-axis sound that is possible with a traditional shotgun microphone.

I’ll discuss the AT895 and the SuperCMIT in upcoming posts. For now, I’ll just say that both of these innovative microphones demonstrated that DSP can dramatically improve shotgun microphone performance, but were hampered by the limitations of then-available DSP technology. That’s no longer an issue, so I expect many more DSP-enhanced directional microphones in the near-future.

References

- W. P. Mason and R. N. Marshall, “A Tubular Directional Microphone,” J. Acoust. Soc. Am., vol. 10, pp. 206-215, (1939). Unfortunately I can’t find a current online source for this reference.

- W. I. Manson, “The Sennheiser Type MD 82 and ElectroVoice Type 642 Microphones”, BBC Research Department Report L-052, 1962. Available at https://rdweb1.lh.bbc.co.uk/rd/publications/rdreport_1962_41 [accessed June 2021].

- Martin Mitchell’s Microphones blog at https://martinmitchellsmicrophones.wordpress.com/2016/12/21/electro-voice-cardiline-microphones-ev642-643-644-circa1960/ [accessed June 2021].